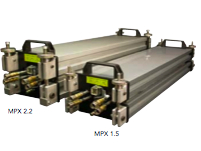

The MPX Lightweight Vulcanizer from Shaw Almex is designed for fast and dependable splicing with P.V.C, Polyurethane and Polyester Mono filament synthetic belting. Constructed using the unparalleled pressing technology from Almex, every MPX is built with:

PLATENS: Custom extruded plank, silicon heating element, and durable composite insulating packaging assembled in flexible platen that fully assumes contour of belt. Efficient heating/cooling cycle with maximum platen temperature of 200°C.

FRAME: Two piece durable aluminum frame is easy for single user to position around belt. MPX frame prole is exceptionally low, with height ranging from only 205mm to 285mm.

CONTROL PANEL: T1R, T2, and T3 Control Panels will accommodate various amp and volt requirements. Panels with additional timer (T2T and T3T) or fully automatic operation feature, including pressure and cooling functions, also available (T2TC and T3TC).

PRESSURE/COOLING: MPX built-to-order with operating pressure of either 1.5kg/ cm2 or 2.2 kg/cm2. Uniform pressure guaranteed with patented Almex pressure bag (air pressure). Press cooled by water channeled through extruded platen using C1M or C1 cooling equipment. New Qwikool System available for dual air pressure and water cooling functions.